General Information on Hexagonal Netting

Traditional Netting – Hexagonal Netting

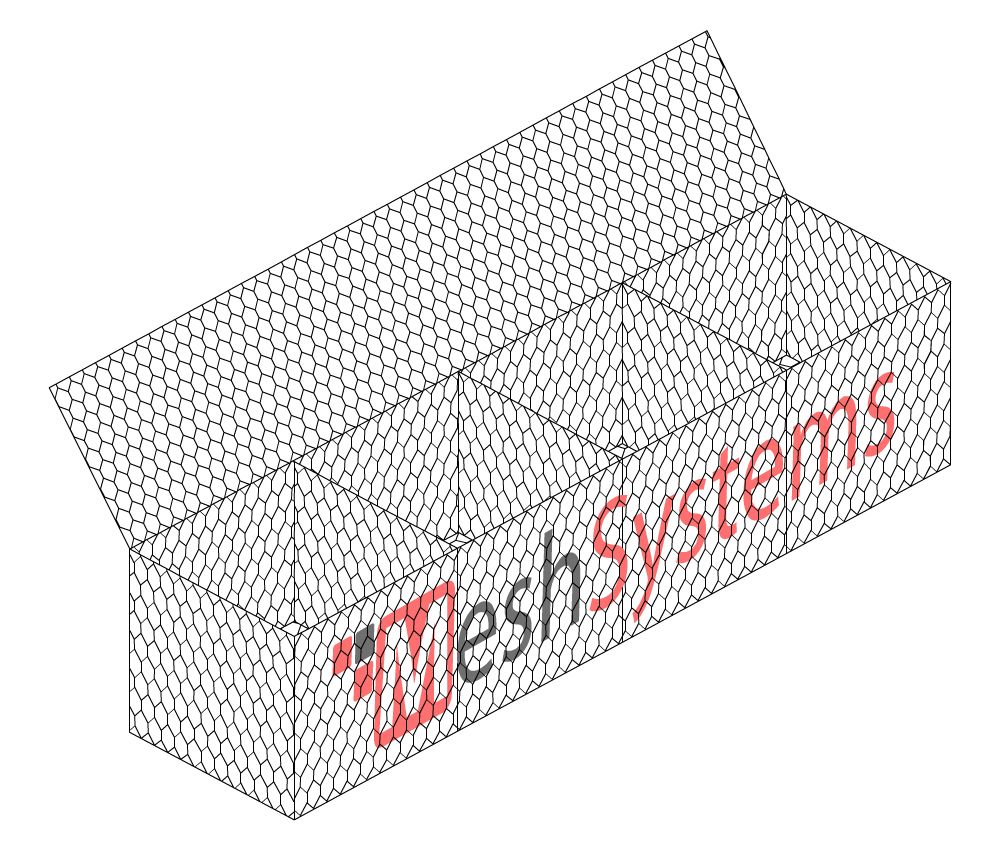

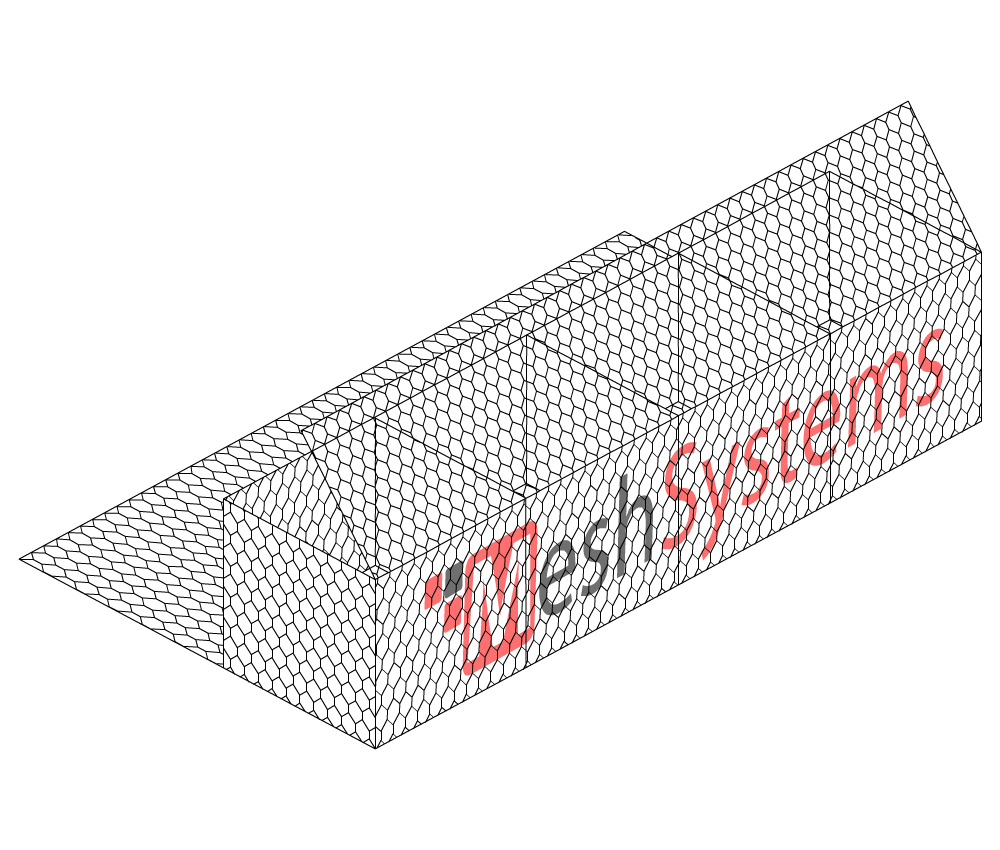

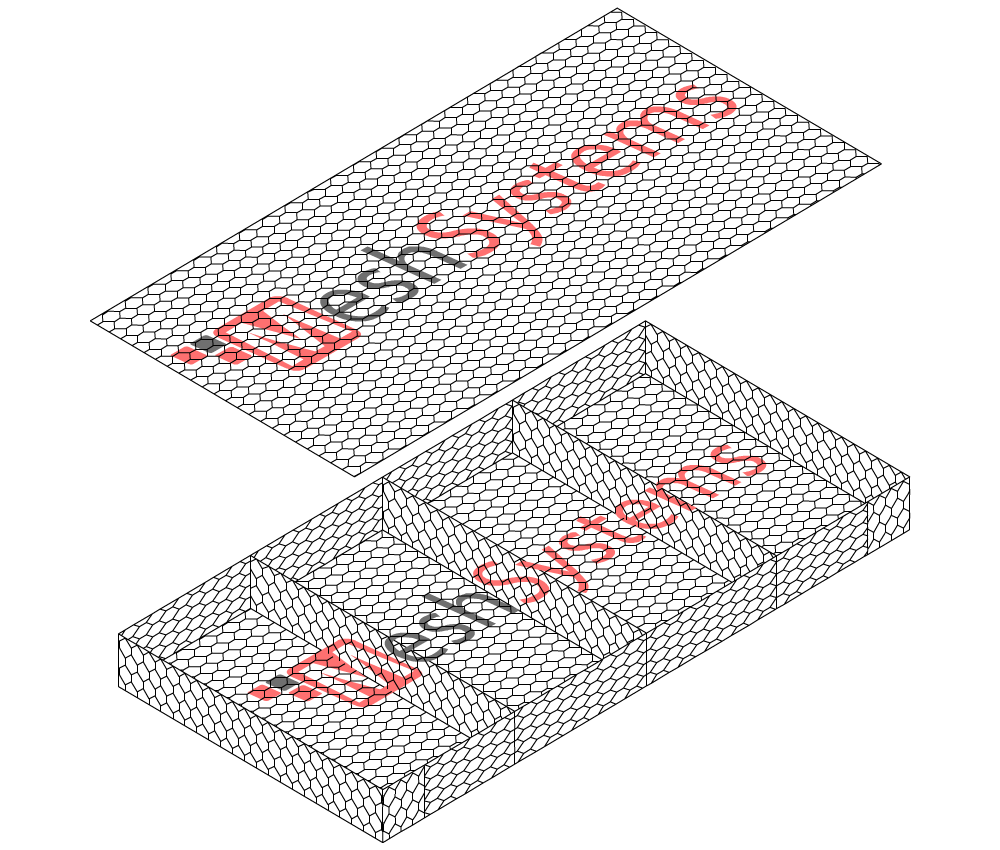

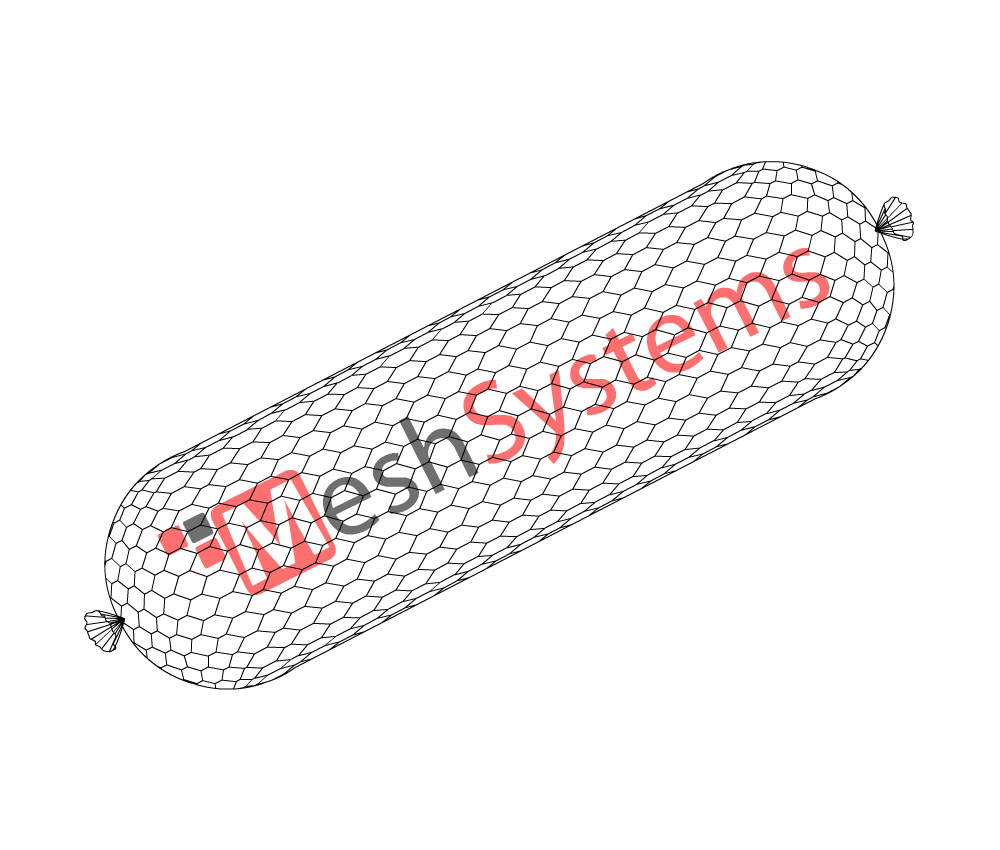

Products made of double twisted hexagonal netting are supplied in the form of gabion baskets, mattresses, sacks or loose mesh packed in rolls. Gabion baskets and mattresses are transported in piled packages, resolved into cuboids on the construction site and connected with hog rings or wire. Depending on the usage, gabions are made in a suitable size and differ in the type of wire used (diameter and anti-corrosion coating) and the number of diaphragms. All products from the hexagonal netting meet the requirements of the National Technical Approval of the Road and Bridge Research Institute and Factory Production Control.

Advantages of Using Hexagonal Netting Products

- PERMEABILITY – cause a free flow of water inside a gabion basket

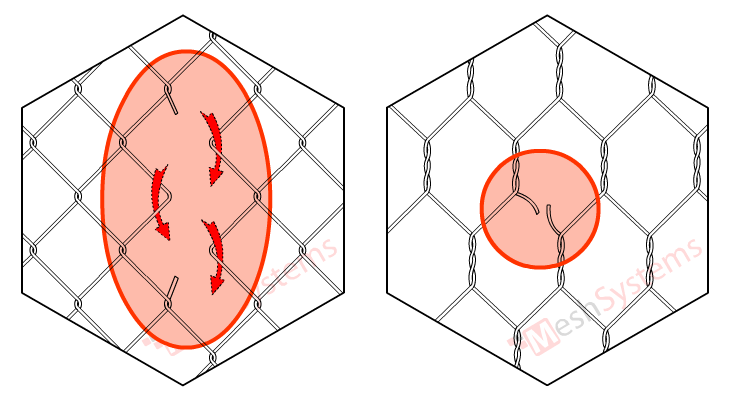

- ADAPTABILITY – ground movements do not cause structural damage

- DURABILITY – mesh structures serve nature much longer than the traditional protective and stabilizing structures

- SOUND INSULATION – gabions are used alongside roads and near objects that emit excessive noise

- INSTALLATION/ASSEMBLY – installation is quick and does not require a large workspace

- ECOLOGY – environmentally friendly assisting microorganisms and plants grow

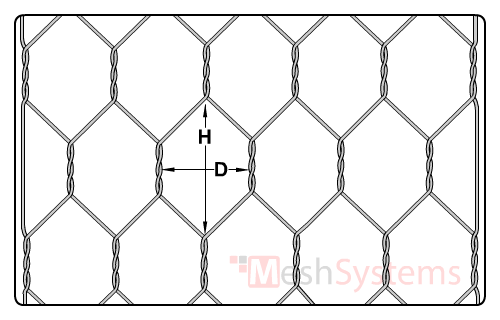

Mesh size DxH (mm)

Material

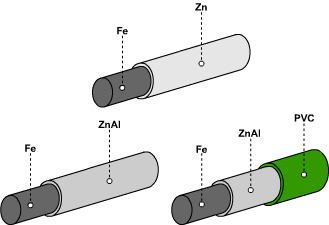

Wire types

Hexagonal netting products are made with wire with diameter of 2.20÷3.50 mm. Depending on the requirements and usage a variety of coatings are applied. The most common anti-corrosion coating is the one made of zinc (Zn) in the amount of 230÷265 g/m2. Another coating is a zinc-aluminum alloy (ZnAl – in the proportion of 95/5%) applied in the amount of 230÷265 g/m2. There is also a variation of wire coated with an extra layer of polyvinyl chloride (PVC) for better protection against corrosion and reducing mechanical damage. All materials used in the production comply with the requirements of EN 10244-2.